Quality Epoxy Floors Begin with Surface Preparation

Epoxy resin floors rely on a strong foundation - often, a strong concrete foundation. And not every concrete floor is going to be the perfect specimen. Sometimes, it'll take a little bit of work to get it prepared. That's why XPS is here to help you learn the ins-and-outs of concrete flooring surface preparation.

An ounce of knowledge and careful preparation will go a long way towards strengthening your epoxy resin. Read our guide to learn what the veterans do to prepare concrete!

How Good Contractors Prepare Concrete Surfaces

Assess Your Concrete's Quality

1. Moisture Assessment

Oft-forgot, but easy to cover! There's no sense in ignoring the possibility that your concrete could contain moisture that would threaten your epoxy resin. No matter the testing route you go, even the most broad test is better than nothing. We've covered your moisture testing options in a separate guide.

Moisture issues may not be immediately apparent. Depending on your climate, they will also appear in different ways. It might be an inability to cure properly, or cracking from the seasonal cycle affecting the moisture.

2. Concrete Repair & Leveling

You don't have to settle for a broken, chipped or cracked concrete floor, so don't. Repairing your concrete is easy and provides a lot of benefits. Aesthetics or utility, repairing your concrete before installing epoxy resin on top of it is essential.

Whether it's a self-leveling compound or grinding, you'll need to take care of the evenness of your floors, too. Epoxy installed on an uneven surface can be unsafe! Whatever your floor cures as is how it'll stay, so try to get it perfect the first time through.

3. Ideal Concrete Surface Profile

Last, but most certainly not least, is ensuring your concrete has the right concrete surface profile (CSP) to bond with epoxy resin. We know; concrete looks beautiful smoothed out. But, for epoxy resin to have the best bond, it needs to be slightly roughened.

There are a few ways to assess and manage your CSP. While the industry no longer recommends acid etching, mechanical grinding still reigns. If your concrete is too rough, you may need to apply a slight top layer of concrete for your epoxy to be built on top of. XPS' online store provides any concrete surface profile management resources, such as grinders, that you'll need!

Prepare the Concrete Floor for Epoxy Resin

1. Cleaning & Surface Preparation

Concrete is a breeze to maintain and clean. That'll come in handy when you're preparing your concrete floors for epoxy resin! It doesn't need to be spotless, though the more thorough you are the better. Sweep any dust, mop with warm water and a gentle cleanser, and you should be good.

If you're going for a glossy, clear coat of epoxy resin for a polished concrete look, you'll want spotless concrete. It'll be worth the extra effort to have your perfect floors!

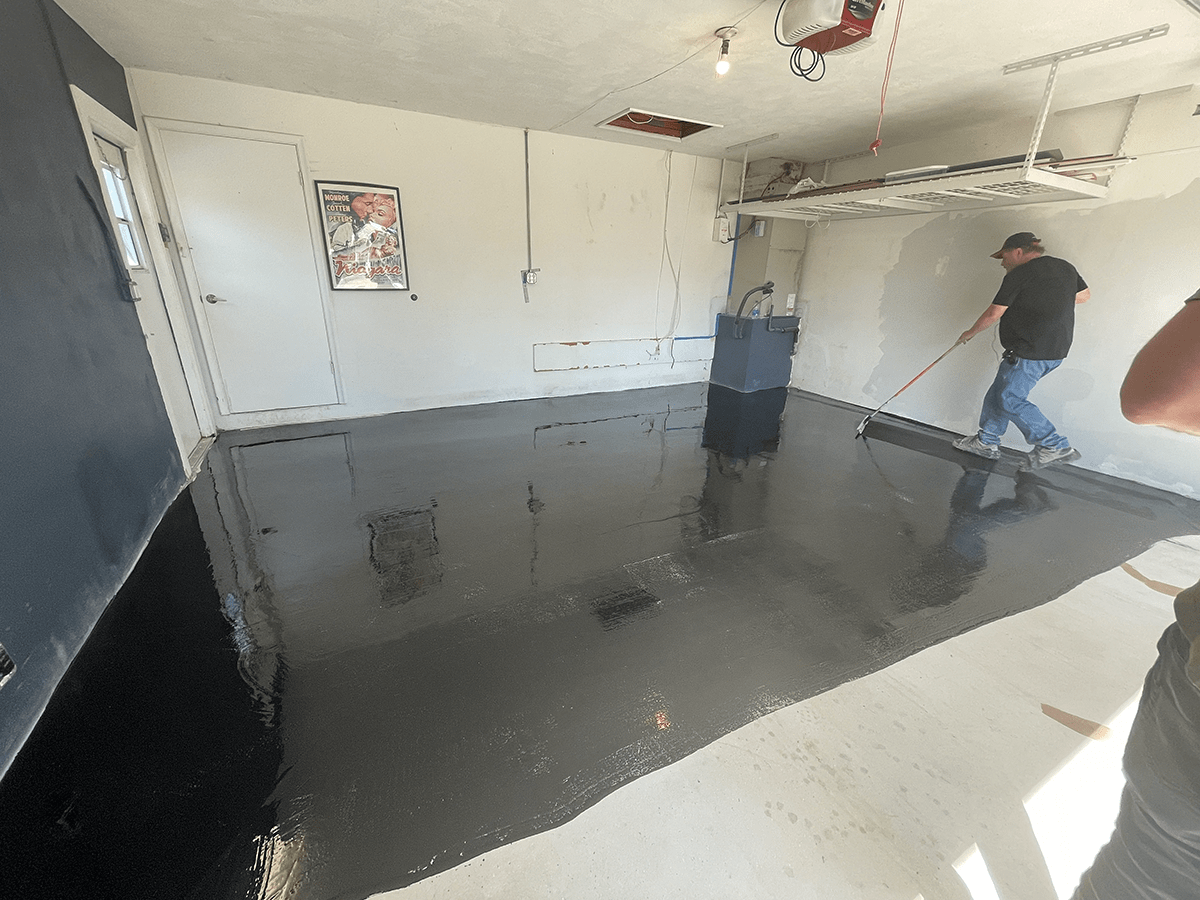

2.. Primer Application

This step is optional, as you could skip straight to epoxy resin installation. But, if you want the strongest possible floors, apply a primer layer! Primer will help not only with leveling out your floors even further, it'll improve its strength, too.

And with that, your concrete floor is ready for a full epoxy resin system installation. If you follow all of these techniques, your floors will be stronger, and more beautiful.

Conclusion

Surface preparation is the keystone that any good epoxy resin installation is built around. Whether you're doing it to improve your aesthetic results, or to improve adhesion & strength, every step is important. So don't get complacent! Practice patience & thoroughness and your clients, and your wallet, will thank you.

Xtreme Polishing Systems (XPS) is the one-stop shop for flooring contractors specializing in concrete & epoxy flooring! Whether its guidance on a job or a product, our technicians are on call at (877) 958-5264 to help you.