Patience for perfection in epoxy floor installations.

As an epoxy contractor, it's the little things that make an epoxy flooring installation turn out perfect. Steps like surface preparation, or getting the timing right on your epoxy curing and drying, are crucial to delivering impeccable results. Patiently waiting for epoxy to cure is the finishing touch in your client's flooring installation.

So don't settle for less anymore! Give your clients a floor to keep for the long term with help from our guide on curing and drying epoxy.

What's Behind Epoxy Curing and Drying Times?

Curing Times

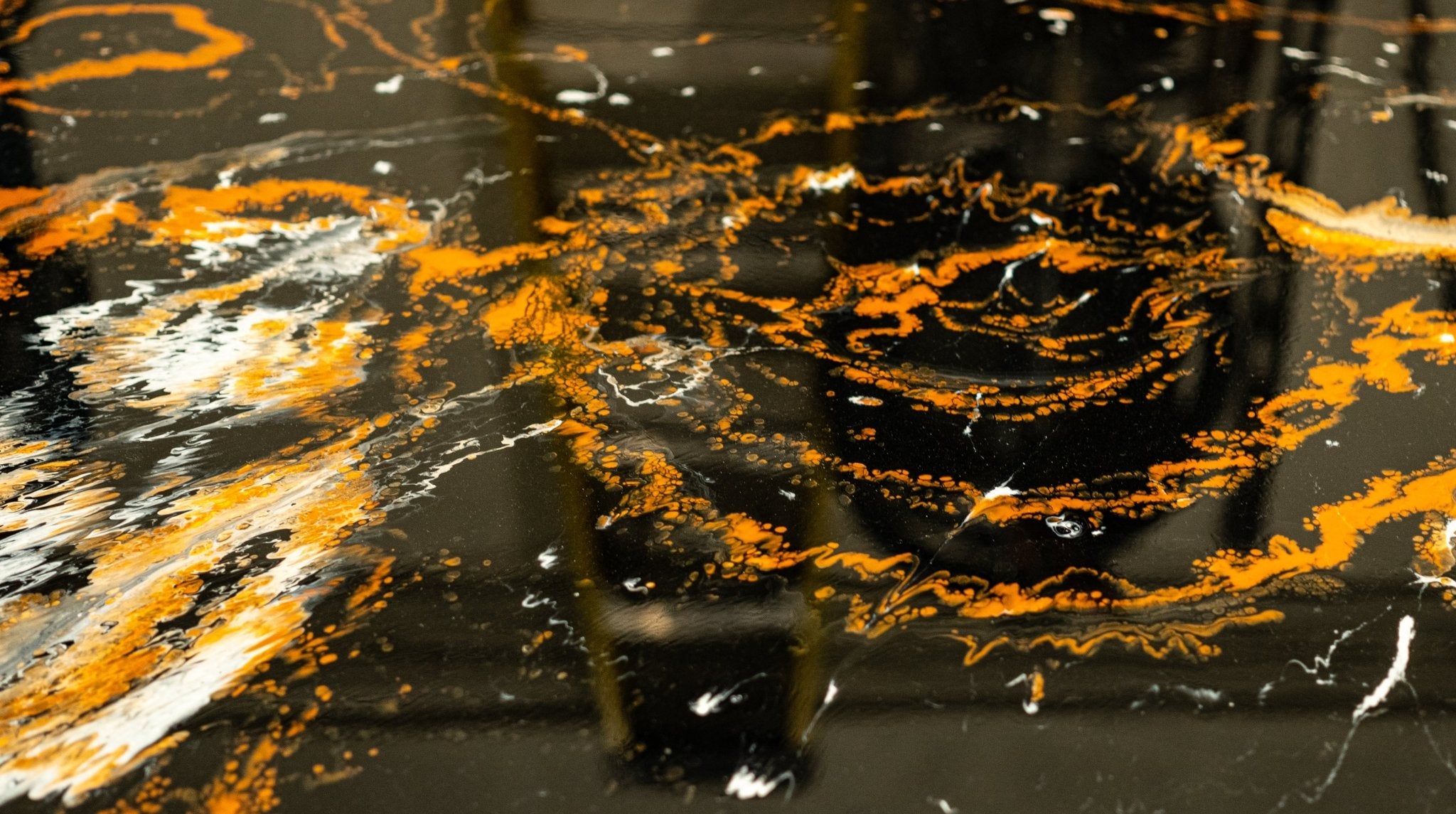

The process of installing an epoxy floor is as chemical as it is physical. Curing is the chemical transformation between your choice of epoxy resin & hardening agent. There's a few common issues that can happen during curing, so be aware!

Most epoxy resins on the market ask for about 24 hours for drying & curing time. However, some epoxy resins need even more time. To be cautious, either check on the manufacturer's instructions for the exact time, or just give your clients a generous 72 hour window before they start using the floor again. It's a small inconvenience that will protect your client's investment!

Chemical Components of Curing

Curing is a chemical dance between epoxy resin and hardening agent. When these components are mixed, they initiate a reaction that causes the epoxy to transition from a liquid to a solid state. That's part of what can make curing and drying tricky; you could set yourself up for issues before an ounce of resin is installed!

The duration of this process primarily depends on the specific epoxy resin, environmental factors, and the accurate mixing of the resin and hardening agent.

Drying Times

Drying time, distinct from curing, is the time that's needed for epoxy to lose its liquid properties and become tack-free. During this phase, the floor still needs to be protected! Despite the epoxy finishing its cure, disturbing the resin during its drying period can still result is unappealing marks, pocks and more.

The reason why we recommend telling clients to not use their floors for 48 to 72 hours is because of drying! For example, a polyaspartic resin floor cures in about 8 hours. That doesn't mean it's perfectly safe for the floor to have foot traffic yet!

Factors in Epoxy Curing and Drying Times

There's a few factors that will affect the duration of your epoxy curing and drying process. We've covered a few already: the correct epoxy resin and hardening agent ratios, foot traffic, and more. Importantly, environmental conditions also play a significant role. Epoxy exposed to warmer or more humid climates requires more time to cure and dry, while cooler environments expedite the process.

Excessive humidity can adversely affect both the curing and drying of epoxy, potentially creating issues with your work timeline. Therefore, it's important to pay attention to detail during installation! Start strong, prepare the surface thoroughly and stay patient and thorough during installation to guarantee a successful outcome.

Solutions to Get the Perfect Epoxy Cure

There's always ways to improve on the job site. It doesn't have to be as significant an investment as a grinder, though it often is. But even the smallest choices can make or break your installation!

Here's a few helpful solutions to keep in mind during your installation:

- Read the manufacturer's instructions! This is the easiest way to get the right advice for your specific resin product.

- Maintain a stable ambient climate in your epoxy resin work area. Radical shifts in temperature, or less temperate climate conditions in general, are avoidable causes of epoxy failure.

- If you're working on a tighter deadline, consider polyaspartic resin. Its quicker cure doesn't come with a sacrifice in quality.

- Work on your measuring & mixing. No matter how much epoxy resin you install, you always need to keep the ratios of your resin and your hardening agent in mind!

- Get your surface preparation perfect! Epoxy resin needs a good, clean, and strong surface to bond to.

- Invest in a high quality epoxy resin! Our XPS online store carries everything you need for epoxy resin flooring, from grinders to resins like our Fast Cure Epoxy Kit.

Comparing Traditional Epoxy and Polyaspartic

We've talked throughout this guide about how epoxy and polyaspartic are good solutions that offer separate benefits. But what really are the differences between the two resin solutions?

Traditional Epoxy:

Pros:

- Exceptional durability, ideal for heavy traffic areas. Industry standard for a reason!

- Proven longevity, the floor you'll be able to keep for years.

Cons:

- Longer curing and drying times compared to polyaspartic.

- Requires more precise environmental conditions for curing. More finicky during curing due to its length.

Polyaspartic:

Pros:

- Rapid curing and drying times, typically within just an afternoon (~4 hours)!

- Suitable for a wide range of applications due to its fast cure.

- Resistant to yellowing when exposed to UV light.

Cons:

- May not be as durable as traditional epoxy in high-impact areas.

- Limited working time due to rapid curing, which demands efficient installation.

Conclusion

Don't fumble at the finish line! End strong with epoxy resin flooring installations by knowing your resin, and being patient while it cures and dries. The curing duration can range from a few hours to several days, but why risk it? Be careful, and let your results speak for themselves!

On the job or off it, we're here to help you! Find all the epoxy resources you need to kickstart your journey in the Xtreme Polishing Systems (XPS) online store. Contact our technicians for any other guidance you need, or follow our blog!